Epilog Fusion G100 - Galvo Laser

- High-speed engraving and easy to use features.

Advanced Marking Solutions - Epilog Fusion Galvo Fiber Lasers

Located in Milpitas, California

Epilog Laser Fusion G100 Galvo Laser

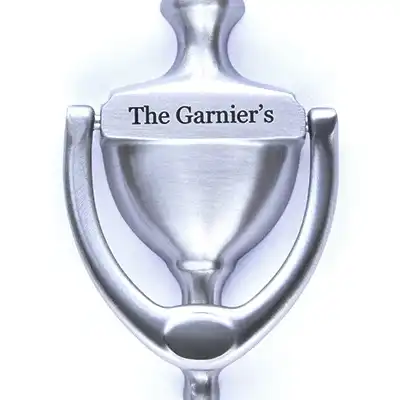

The Fusion Galvo by Epilog Laser combines fast engraving of metals with quick and efficient project setup. This innovative laser machine produces a variety of marks on metal, including deep engraving, polished white marks, and deep black annealed etching. Project setup is fast and easy using Epilog’s Laser Dashboard and artwork placement is exceptionally precise thanks to the IRIS™ camera system. The Fusion Galvo features an exceptionally user-friendly interface and uses high-quality parts and components, giving you unbeatable metal etching results.

Quick View Specs - Fusion G100 - Fiber Galvo

| Work Areas | F163 Lens: 4" x 4" (101 x 101 mm) |

| F254 Lens: 6" x 6" (152 x 152 mm) | |

| Max. Material Height | F163: 10" (254 mm) |

| F254: 6" (152 mm) | |

| Laser Source & Power | Fiber, air-cooled, 1064nm |

| 30-watt pulsed, 30-watt MOPA, or 60-watt MOPA | |

| IRIS™ Camera System | 2 Overhead - Live-View Positioning |

| Rotary Attachment | Optional Add-On |

Standard Features & Recommendations:

- Made-in-the-USA Quality

- 60 IPS Highest-Speed Engraving

- IRIS™ Camera Positioning

- Touch Screen at the Laser

- Print from Windows CAD and design software

- Connectivity: Wireless, USB, and Ethernet

- SAFEGUARD™ Features

- Store Projects at the Laser (1GB Storage)

- High-speed Galvonometer Engraving

Recommended Exhaust:

450-650 CFM (764-1104 m3/hr) external exhaust

to the outside or internal filtration system.

Filtrabox

- Watch the Fusion G100 in Action!

Request Info or Schedule a Demo Today!

Our MADE-IN-USA products and business solutions will take your idea to the next level.

Request Info or Schedule a Demo Today!

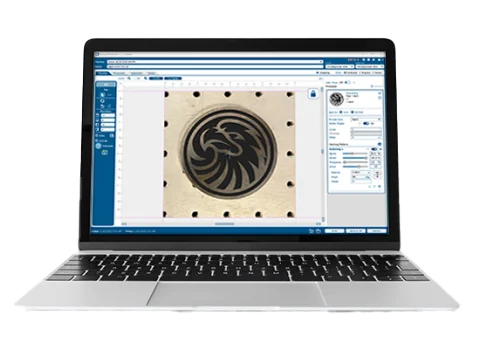

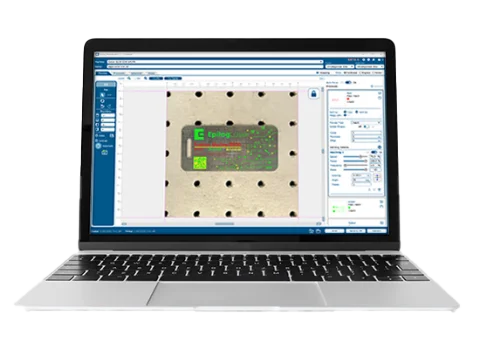

Epilog Dashboard - IRIS Camera Live-Preview

No Complicated

Programming Involved

Two Work Field Choices

Two Lenses, Two Cameras,

Two Field Choices

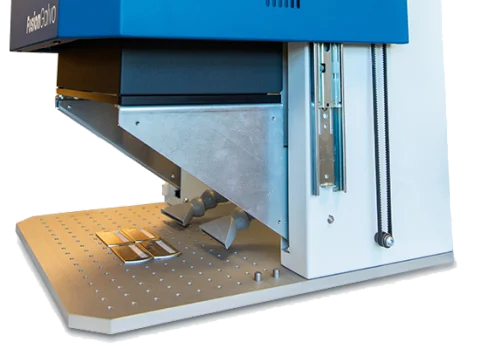

Automated Door

Automated Door for Quick Changing of Parts

Accurate Camera Positioning of Your Artwork

Drag and Drop Camera Positioning

Spend less time aligning your artwork with the Fusion Galvo’s IRIS™ Camera. Two cameras located above the work area allow you to position your graphics perfectly on even the most uniquely shaped items. Drag and drop your artwork on screen, choose your engraving settings, and send the file to the laser in seconds.

- Process Custom Parts with Speed and Precision

Features & Machine Design Enhancements

- Variable Work Area: 4"x4" and 6"x6"

- Two Lenses Included

- Automated Mechanical Door

- Software Versatility

- Design While the Laser Is Operating

- IRIS™ Camera Positioning

- Job Trace Preview

- Touch Screen at the Laser

- Network Your Laser Across Your Business

- Multiple Files at the Galvo

- Memory in the Machine

- Red Dot and Auto Focus

- Integrated Exhaust Controller

- Engineered & Manufactured in the USA

Product features and configurations subject to change without notice.

Metal & Plastic Marking Applications

Material Compatibility

With the Fusion Galvo, engrave and mark a wide array of metals and engineered plastics.

| 17-4 PH stainless steel | 303 stainless | 4043 steel | 6061 Aluminum |

| ABS (white/black) | Aluminum, 6061 | Aluminum, yellow chromate | Bayer 2807 Makrolon polycarbonate |

| Bayers bayblend FR110 | Black/white ABS | Black/white polycarbonate | Brass |

| Brushed aluminum | Carbon nanotube | Ceramics, metal-plated | Clear coat anodized aluminum |

| Cobalt chrome steel | Colored delrin (black/brown) | Compacted powder iron with phosphate coating | Copper |

| DAP – Diallyl Phthalate | Delrin, colored (black/brown) | GE Plastics polycarbonate resin 121-R | Glass filled PEEK |

| Glass filled Teflon | Hard coat anodized aluminum | Inconel metals (various) | Machine tool steel |

| Magnesium | Metal-plated ceramics | Molybdenum | Nickel plated 1215 mild steel |

| Nickel plated brass | Nickel plated gold | Nickel plated Kovar | Nickel plated steel |

| Nylon | PEEK, white | Polybutylene Terephthalate | Polycarbonate (black/white) |

| Polycarbonate resin 121-R, GE Plastics | Polycarbonate, Bayer 2807 Makrolon | Polysulphone | Rynite PET |

| Santoprene | Silicon carbide | Silicon steel | Silicone wafers |

| Stainless steel 303 | Stainless steel 17-4 PH | Steel 4043 | Steel, machine tool |

| Various inconel metals (nickel-chromium super alloys) | White PEEK | Yellow chromate aluminum | Zinc plated mild steel |

| And Many More! |

Request Info or Schedule a Demo Today!

Our MADE-IN-USA products and business solutions will take your idea to the next level.

Technical Specifications

Fusion G100 - Fiber Galvo Laser

| Work Area: | F163: 4" x 4" (101 x 101 mm) F254: 6" x 6" (152 x 152 mm) |

| Material Thickness: | F163: 10" (254 mm) F254: 6" (152 mm) |

| Laser Source: | Fiber, air-cooled, 1064nm |

| Laser Tube Wattages: | 30-watt pulsed, 30-watt MOPA, or 60-watt MOPA fiber configurations |

| IRIS™ Camera Positioning: | 2 overhead |

| Laser Connectivity: | Wireless, USB, and Ethernet |

| Included Lenses: | F163 and F254 lens |

| Resolution: | Fully-flexible & user-controlled from 75 – 1200 dpi |

| Maximum Engraving Speed (inches/meters per second): | 60 IPS (1.5 m/s) with 3.5G acceleration. Computer-controlled in .001 increments up to 100%. Color mapping feature links Speed, Power, Frequency, and Raster/Vector mode. |

| Print Driver & Software: | Laser Dashboard™, Epilog Job Manager™ |

| Internal Memory: | Store multiple files up to 1 GB. Engrave any file size. |

| Operating Modes: | Optimized Raster, Vector, and Combined mode. |

| Super-Silent Cooling Fans: | Included |

| Job Trace: | Included |

| Auto Focus: | Included |

| Touch Screen: | Included |

| Size (W x D x H): | 28" x 23" x 31" (door closed) 37" height (door open) |

| 711mm x 584mm x 787mm / 940mm | |

| Weight: | 131 lbs (59.5 kg) |

| Electrical: | Auto-switching 110 to 240 volts, 50 or 60 Hz, single phase, 15 amp AC |

| Ventilation: | 450-650 CFM (764-1104 m3/hr) |

| Saftey Rating: | Class 2 Laser Product – 1 mW cW MAXIMUM 600-700nm |