Epilog Fusion Pro Laser Machines

- Epilog's highest-quality engraving and cutting at industry leading speeds.

Advanced Marking Solutions - Epilog Fusion Laser Cutters

Located in Milpitas, California

Epilog Fusion Pro Laser Engravers & Cutters

Fusion Pro Laser Feature Overview

It’s our new concept in laser system design, featuring:

- 24" x 24", 36" x 24", or 48" x 36" engraving area

- Engrave items up to 12.25" in material height

- 5G acceleration and 165 IPS engraving speeds

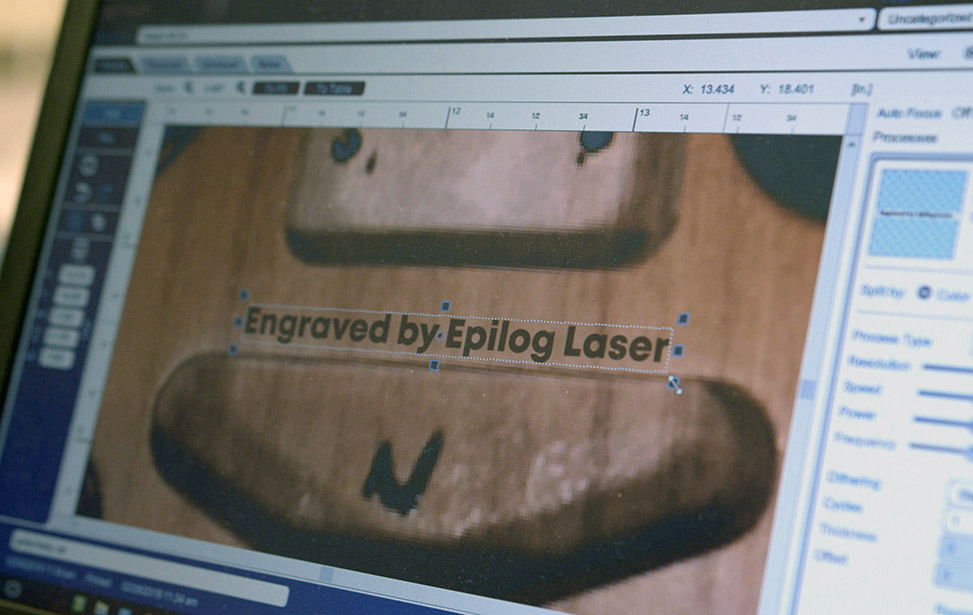

- IRIS™ Camera Positioning system for quick optical registration

- Touch Screen controls at the laser system

- Our new standard for motion control design

- New SAFEGUARD™ features to reduce frequency of cleaning and maintenance

- Flame-polished finished edge cuts

- Large viewing door and internal LED lighting

And we’re proud to say it is 100% designed, engineered and built in the USA!

Fusion Pro 24 | Fusion Pro 36 | Fusion Pro 48 | |

|---|---|---|---|

Work Area | 24" x 24" x 9" (610 x 610 x 228 mm) | 36" x 24" x 9" (914 x 610 x 228 mm) | 48" x 36" x 12.25" (1219 x 914 x 311 mm) |

Laser Options | CO2, Fiber, or Dual Source | CO2 or Dual Source | CO2 or Dual Source |

CO2 | 60 or 80 watts | 60 or 80 watts | 80 or 120 watts |

Fiber | 30 or 50 watts | n/a | n/a |

Dual Source | CO2: 60 watts / Fiber: 30 watts | CO2: 60 or 80 watts / Fiber: 30 or 50 watts | CO2: 120 watts / Fiber: 50 watts |

IRIS™ Cameras | 2 overhead + registration |

Features of the Fusion Pro Laser Series

Highest-Speed Engraving Over Largest Work Area

The Fusion Pro’s 165 IPS engraving speed and 5G acceleration combine to provide the fastest engraving in the industry.

IRIS™ Camera Positioning

Overhead cameras provide an accurate picture of the working area for accurate artwork placement, and a camera at the lens allows the system to find preprinted registration marks.

Touch Screen at the Laser

Select between jobs, change settings, and more right from the easy-to-use touch screen interface at the laser. Manage your print jobs and rerun with the touch of a button.

Engineered and Manufactured in the USA

Proudly designed, engineered, and manufactured in our Golden, CO headquarters at the base of the Rocky Mountains.

Network Your Laser Across Your Business

SAFEGUARD™ Features

Air Assist and Compressor

The air assist removes heat and combustible gases from the cutting surface for a cleaner cut. A built-in air compressor provides air directly to the work surface.

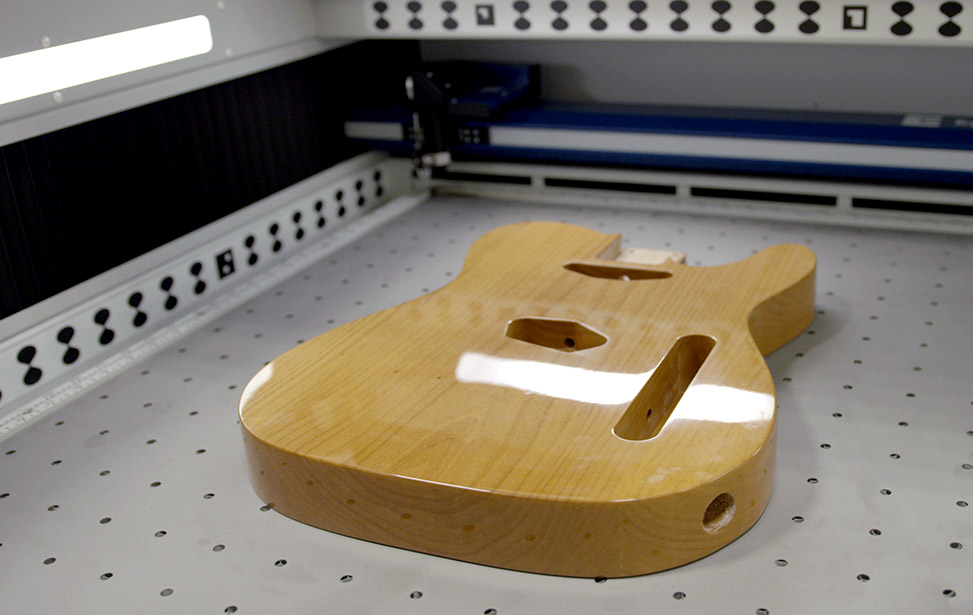

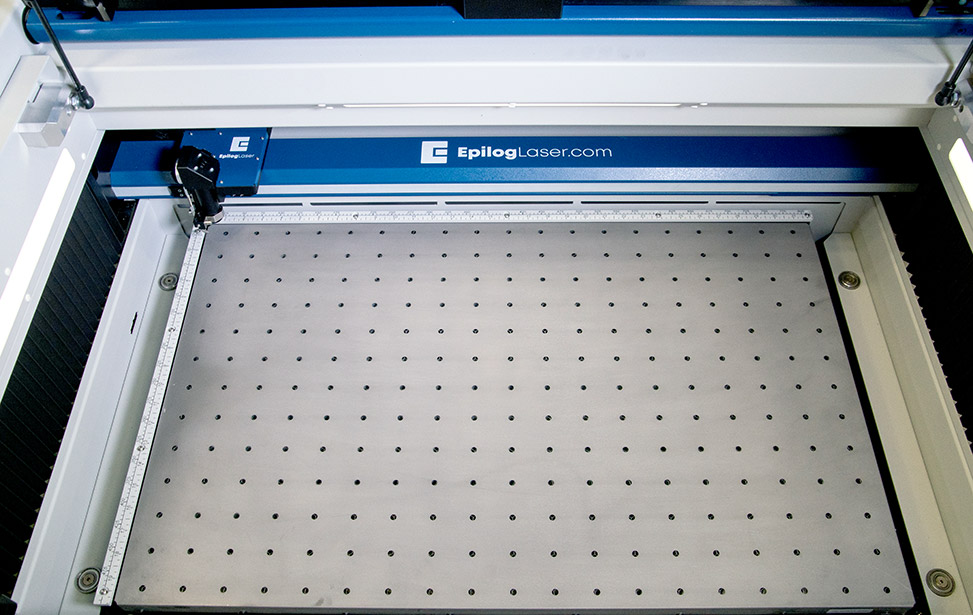

Table Choices

Choose between a flat engraving bed, honeycomb cutting table, and slat cutting table to suit your project needs. The table is in two sections, allowing you to mix and match your table across the bed.

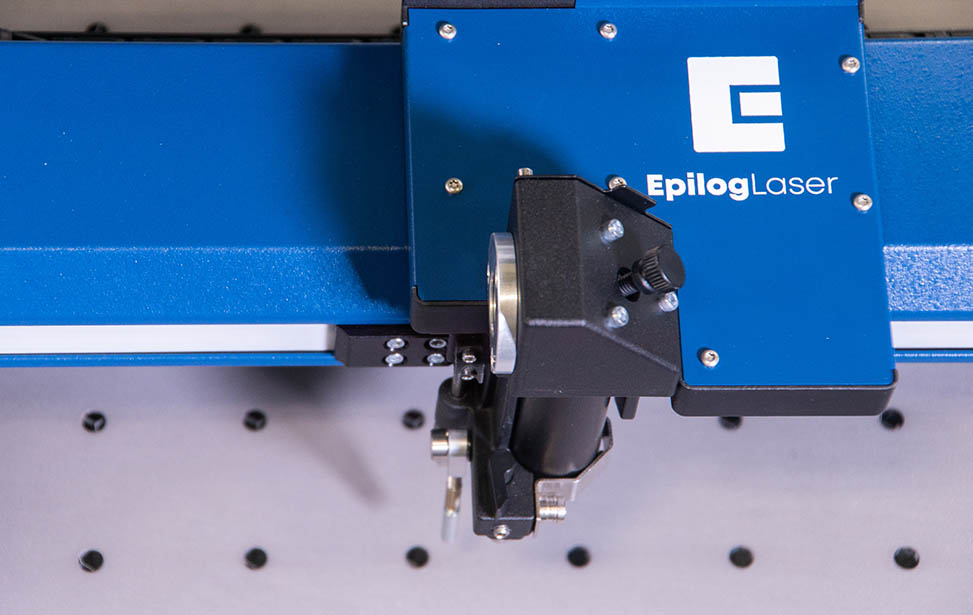

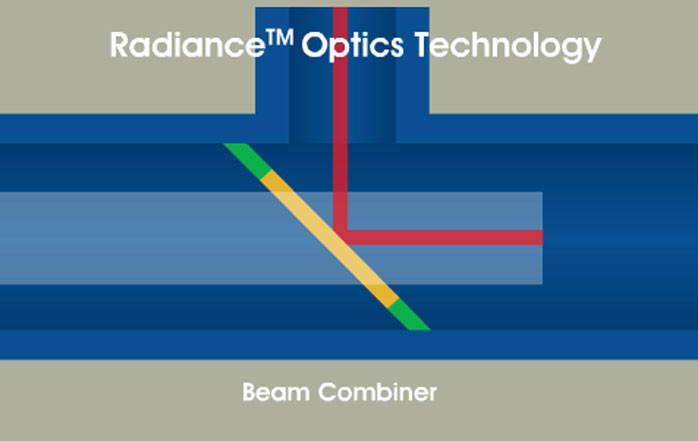

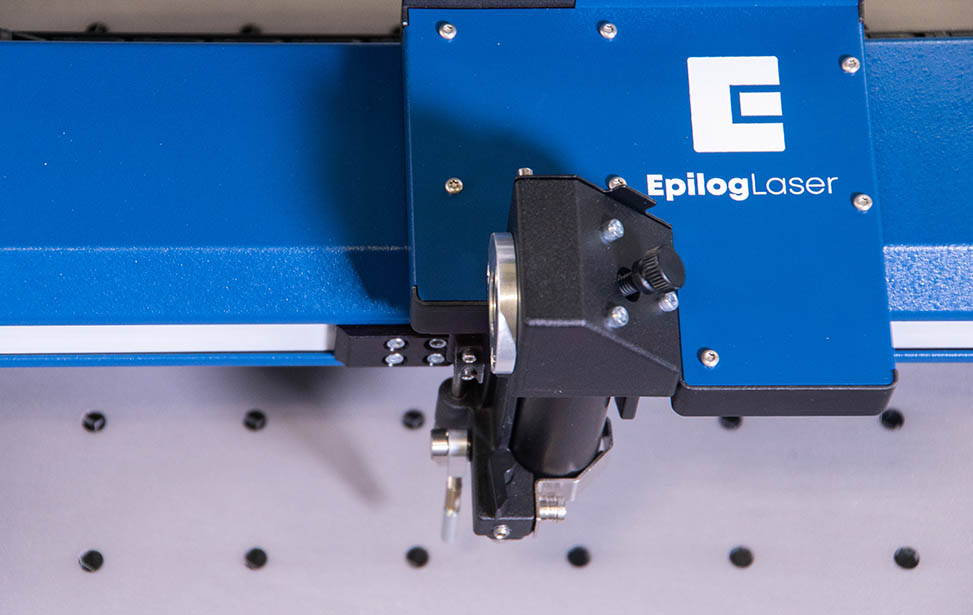

Radiance™ Beam Enhancing Optics

Epilog’s laser beam enhancing lens package for the highest quality engraving across the entire table comes standard with the Fusion Pro series.

CO2 Metal Laser Tubes by Epilog

All-metal tube design provides higher beam quality and longer life with low recharge costs.

1 GB Memory in the Machine

Improve job management and data integrity with 1GB of RAM in both Fusion Pro systems. Save your most run jobs right at the laser.

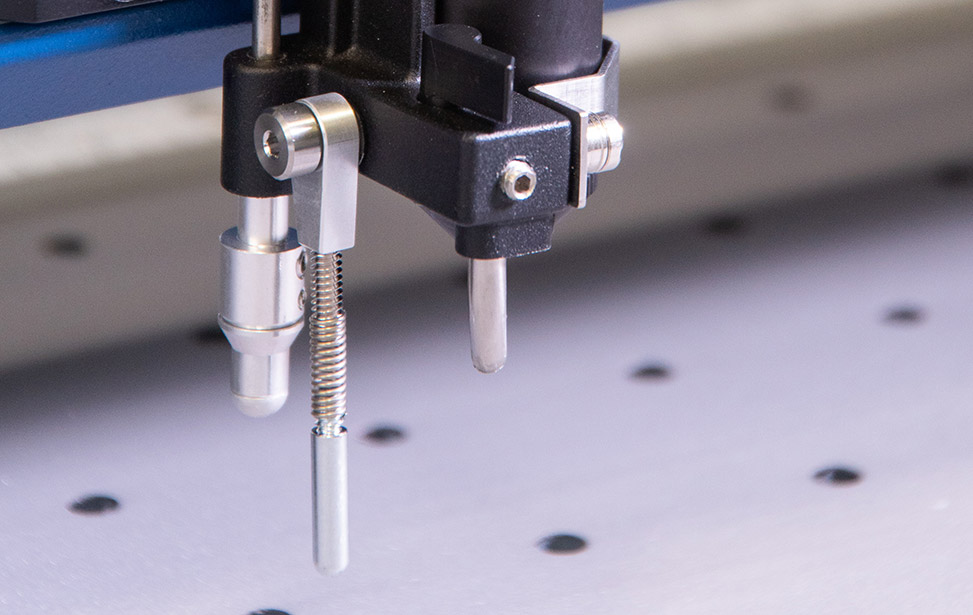

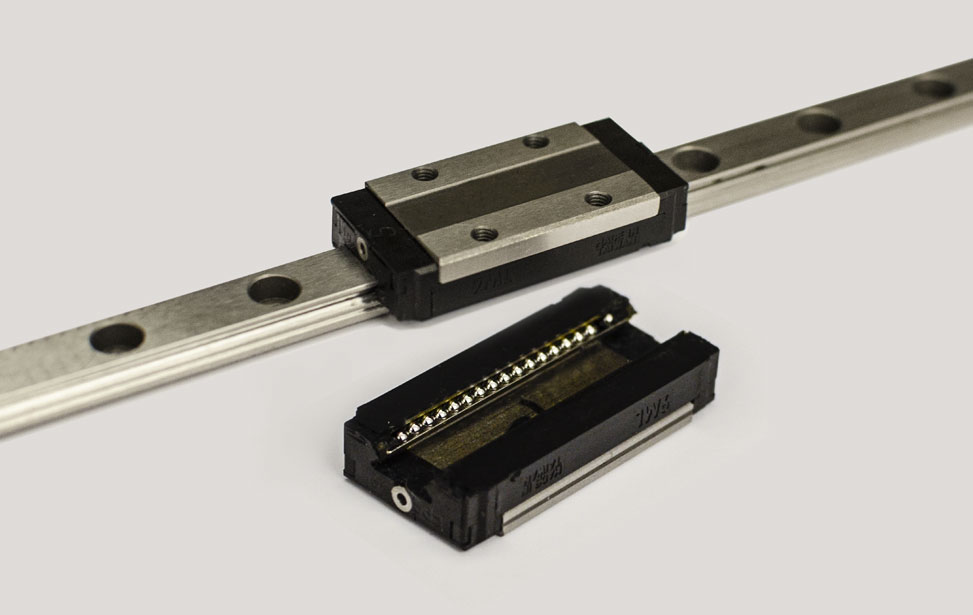

Long-Life Steel Bearing

A dual block design provides the most rigidity and reduced vibration without the inevitable wobble and replacement of plastic bearings.

Epilog Fusion Accessories

Dual Source Option: CO2 and Fiber

Dual Source Option: COCombine the fiber laser's metal etching capabilities to the CO2 laser's versatility. 2 and Fiber

Are you looking for the ability to directly etch metals in addition to the material versatility of the CO2 laser? Add on the dual source option to your Fusion Pro and choose a CO2 laser (50, 60, 75, or 120 watts) and add on a fiber laser (30 or 50 watts) to work with a wider range of materials.

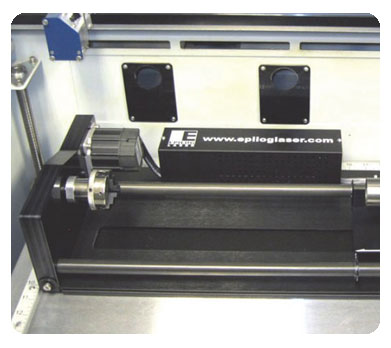

Fusion Rim-Drive Rotary Attachment

The Standard Rim-Drive Rotary Attachment allows you to engrave wine bottles, mugs, glasses and more.

Available for the Fusion Laser, the Standard Rotary Attachment adds the ability to engrave bottles, glasses, flashlights, or any other cylindrical item up to 11.25″ (286 mm) in diameter. The Fusion Laser rotary attachment has been built to accommodate a large variety of shapes and sizes. Setup is as easy as placing your product on the Rotary Attachment, raising or lowering the scissor lift to level the engraving area, and printing to the laser!

Fusion 3-Jaw Chuck Rotary Attachment

When more precision is required, the 3-Jaw Chuck Rotary Attachment is the ideal choice.

Only available for the Fusion Laser, the 3-Jaw Chuck mechanically clamps a cylinder or oddly-shaped, non-cylindrical item place as the laser engraves.

The Fusion Laser rotary attachment has been built to accommodate a large variety of shapes and sizes. Setup is as easy as placing your product on the Rotary Attachment, raising or lowering the scissor lift to level the engraving area, and printing to the laser!

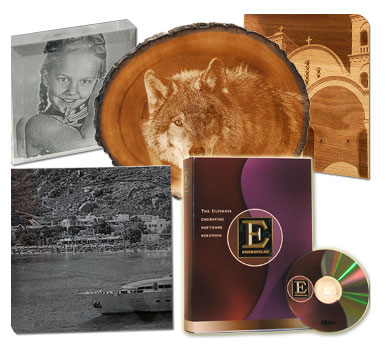

PhotoLaser Plus Software

Photo processing software that optimizes your photographs for engraving on a variety of materials.

PhotoLaser Plus takes photo engraving with your Epilog Fusion Pro laser to the next level by easily processing photos for engraving on all types of materials.

Are you looking for a system that engraves outstanding photographs? How about a system that engraves photos in a consistent, predictable way for your customers?

Epilog Laser has partnered with CADLink to bring you the industry’s best photo processing software: PhotoLaser Plus. The easy-to-use software interface and powerful photo processing tools allow you to create the highest-quality photo engravings in the industry.

Optional Lenses

In addition to the 2.0" lens, we offer special lenses for specific applications.

1.5″ Lens: Highest-Resolution Engraving

Although the standard 2.0 inch lens provides amazing detail, our 1.5-inch lens assembly has been designed for the highest-resolution engraving and etching of extremely small fonts.

4.0″ Lens: Cutting Thicker Materials and Inside Deep Areas

The 4.0 inch lens produces a focused beam over a longer vertical distance, which makes it ideal when engraving within a recessed area of a product, such as inside a bowl or plate. The lens is also used for cutting through very thick materials.

Cone Lens: Deep Cutting with the Laser

The Cone design pushes the stream from the Air Assist down directly through the cut, rather than over the surface of the engraving material. This provides even better reduction of laser flare-ups and better edge quality.

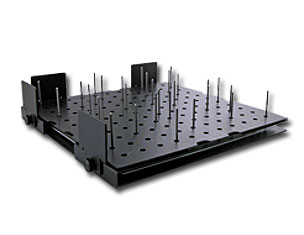

Vector Pin Table

Raise and support your cutting materials for better edge quality.

The Pin Table incorporates movable pins that can be placed anywhere along the table’s grid of one inch (25.4 mm) spaced holes. The movable pins also allow the user to raise and support the cutting material in locations where the laser will not be cutting, providing a means of eliminating backside reflection. The table also allows you to place pins to support parts that would normally fall out of the cutting pattern. A handy removable surface plate makes the task of cleaning up small parts easy without removing the Pin Table.

Epilog Fusion Pro CO2 Compatible Materials

Engrave | Cut | |

|---|---|---|

Wood | x | x |

Acrylic | x | x |

Fabric | x | x |

Glass | x | |

Coated Metals | x | |

Ceramic | x | |

Delrin | x | x |

Cloth | x | x |

Leather | x | x |

Marble | x | |

Matte Board | x | x |

Melamine | x | x |

Paper | x | x |

Mylar | x | x |

Pressboard | x | x |

Rubber | x | x |

Wood Veneer | x | x |

Fiberglass | x | x |

Painted Metals | x | |

Tile | x | |

Plastic | x | x |

Cork | x | x |

Corian | x | x |

Anodized Aluminum | x | |

Stainless Steel | * | |

Brass | * | |

Titanium | * | |

Bare Metals | * | |

* CO2 lasers will mark bare metals when coated with a metal marking solution. For more information, visit our laser metal marking page. | ||

Do you have a material you would like us to test? Give us a call 480-557-7999. |

Epilog Fusion Pro Fiber Compatible Materials

- 17-4 PH stainless steel

- 303 stainless

- 4043 steel

- 6061 Aluminum

- ABS (white/black)

- Aluminum, 6061

- Aluminum, yellow chromate

- Bayer 2807 Makrolon polycarbonate

- Bayers bayblend FR110

- Black/white ABS

- Black/white polycarbonate

- Brass

- Brushed aluminum

- Carbon nanotube

- Ceramics, metal-plated

- Clear coat anodized aluminum

- Cobalt chrome steel

- Colored delrin (black/brown)

- Compacted powder iron with phosphate coating

- Copper

- DAP - Diallyl Phthalate

- Delrin, colored (black/brown)

- GE Plastics polycarbonate resin 121-R

- Glass filled PEEK

- Glass filled Teflon

- Hard coat anodized aluminum

- Inconel metals (various)

- Machine tool steel

- Magnesium

- Metal-plated ceramics

- Molybdenum

- Nickel plated 1215 mild steel

- Nickel plated brass

- Nickel plated gold

- Nickel plated Kovar

- Nickel plated steel

- Nylon

- PEEK, white

- Polybutylene Terephthalate

- Polycarbonate (black/white)

- Polycarbonate resin 121-R, GE Plastics

- Polycarbonate, Bayer 2807 Makrolon

- Polysulphone

- Rynite PET

- Santoprene

- Silicon carbide

- Silicon steel

- Silicone wafers

- Stainless steel 303

- Stainless steel 17-4 PH

- Steel 4043

- Steel, machine tool

- Various inconel metals (nickel-chromium super alloys)

- White PEEK

- Yellow chromate aluminum

- Zinc plated mild steel

- And Many More!

Epilog Fusion Pro Tech Specs

Fusion Pro 24 | Fusion Pro 36 | Fusion Pro 48 | |||

|---|---|---|---|---|---|

Work Area | 24” x 24” (610 x 610 mm) | 36” x 24” (914 x 610 mm) | 48” x 36” (1219 x 914 mm) | ||

Maximum Z-Depth

| 9” (228 mm) | 9” (228 mm) | 12.25” (311 mm) | ||

Laser Tube Wattage | CO2 - 50, 60, or 80 watt

Fiber - 30 or 50 watt

Dual Source - CO2 50, 60, or 80 watt with Fiber 30 or 50 watt | CO2 - 50, 60, or 80 watt

Dual Source - CO2 50, 60, or 80 watt with Fiber 30 or 50 watt | CO2 - 50, 60, 80, or 120 watt

Fiber - 30 or 50 watt

Dual Source - CO2 50, 60, 80, or 120 watt with Fiber 30 or 50 watt | ||

Included Lens | 2" - CO2 3" - Fiber & Dual-Source | ||||

Optional Lenses | 4" - CO2 | ||||

Included Table | Vector Cutting Table (Grid-Style)

| Task Plate | |||

Air Assist Pump | Optional | Optional | Included | ||

Status Light | Included | n/a | |||

Software | Epilog Laser Software Suite: Laser Dashboard™ & Epilog Job Manager™ | ||||

Memory | Multiple files up to 1 GB. Engrave any file size. | ||||

Operating Modes | Optimized Raster, Vector, and Combined modes | ||||

Motion Control | High-speed, continuous-loop, brushless DC servo motors using rotary encoding technology for precise positioning | ||||

X-Axis Bearings | Ground & polished stainless steel, Teflon-coated, self-lubricating bearings. Dual blocks on X-axis for greater rigidity | ||||

Belts | Advanced B-style double-wide Kevlar precision drive belts. | ||||

Resolution | Fully-flexible and user-controlled from 75 – 1200 dpi | ||||

Speed and Power | 165 IPS (4.2m/s) with 5G acceleration. Computer-controlled in .001 increments up to 100%. Color mapping feature links Speed, Power, Frequency, and Raster/Vector mode. | ||||

Print Interface | 1000Base-T Ethernet, USB. Windows 7/8/10 compatible | ||||

Size (W x D x H) | 41.52” x 32.81” x 40.54" 1055 x 834 x 1029 mm | 53.52” x 32.81” x 40.54" 1359 x 834 x 1029 mm | 70.6” x 51.3" x 42.75" 1794 x 1304 x 1086 mm Pedestal removed: 34” H (863 mm) | ||

Weight | 240 lbs (108 kg) | 275 lbs (124 kg) | 650 lbs (295 kg) | ||

Electrical | 110 to 240 volts, 50 or 60 Hz, single phase | 240 volts, 50 or 60 Hz, single phase | |||

Ventilation | 350-400 CFM (595-680 m3/hr) external exhaust to outside or internal filtration unit required. One output port, 4" (102 mm) diameter | Three total ports. Two upper exhaust ports, one lower vacuum table port. Total 735 CFM required. All ports 4” (102mm). | |||

Safety | Class 2 Laser Product – 1 mW CW Maximum 600 – 700 nm |